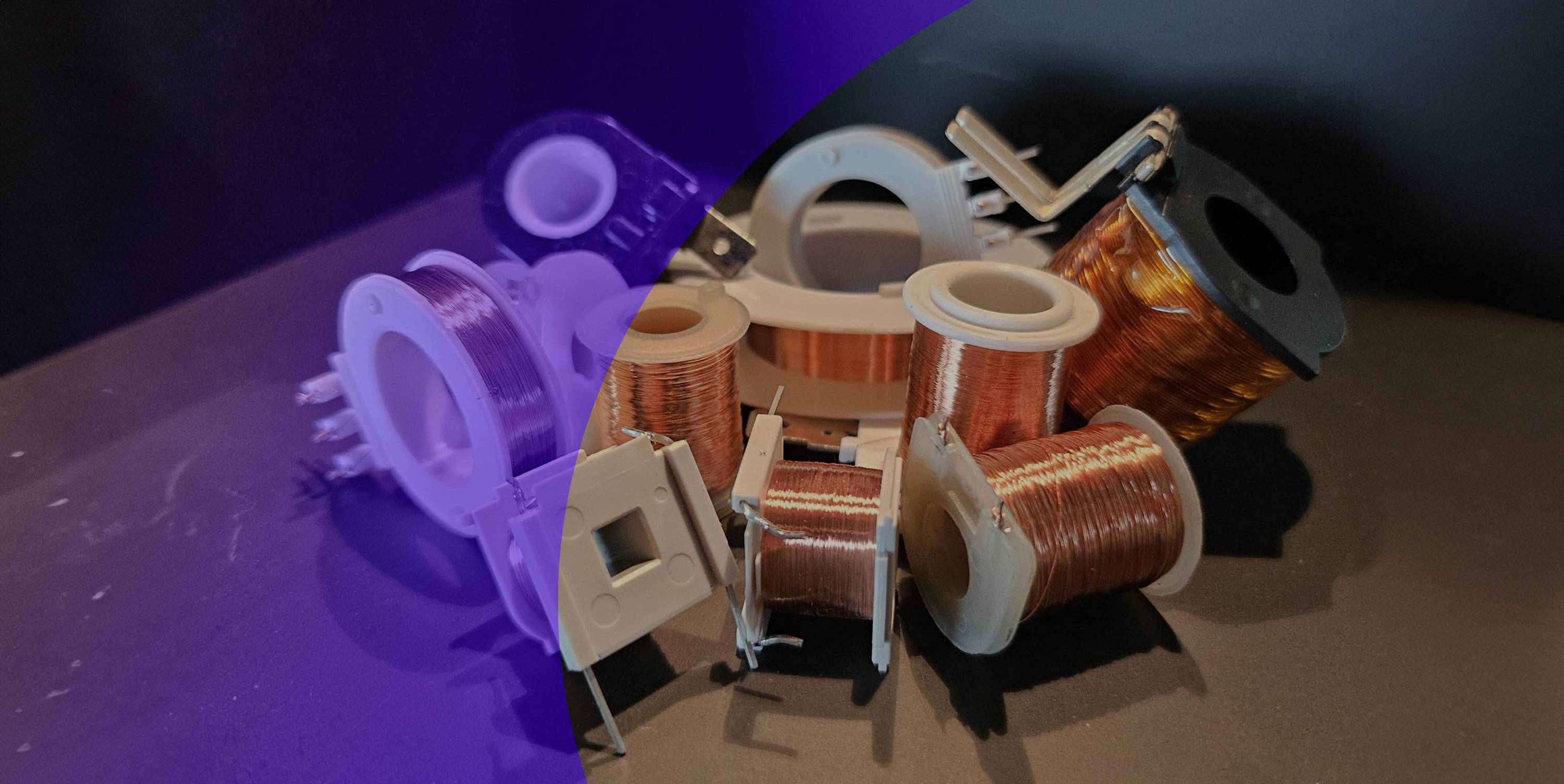

In the production process of coil windings, correctly loading the coils onto the winding machine is a crucial phase to ensure precision, efficiency and quality of the final product. There are various loading methods, each with specific characteristics, tailored to different production needs. Below, we will explore the main coil loading methods, outlining the advantages and applications of each.

Solutions for automatic loading and unloading

Front loading on a loading bar is the most commonly used technique by Eternal Automation and is the most cost-effective for the customer. Semi-automatic loading combines the benefits of both manual and automatic loading. In this case, the operator places the bobbins into a device that automatically aligns and loads them onto the winding machine. This technique offers a good balance between flexibility and speed, reducing manual workload and improving process efficiency.

Automatic loading with a bowl feeder is an ideal solution for high-intensity production and large volumes. Bobbins are loaded onto the machine without human intervention, reducing setup times and minimizing the risk of errors. This method is particularly efficient in production lines where a continuous and steady flow is required.

This technology involves the use of an automated lateral shuttle that transports the bobbins, manually loaded by the operator onto the spindles, directly onto the machine and vice versa. Automatic loading with a lateral shuttle is a useful solution for customers using irregularly shaped cores, allowing the operator to check for any anomalies during loading and to correct or discard the core if necessary.