EZTU and EUTB: innovation in transformer manufacturing

Automatic winding machine with insulation sleeve insertion

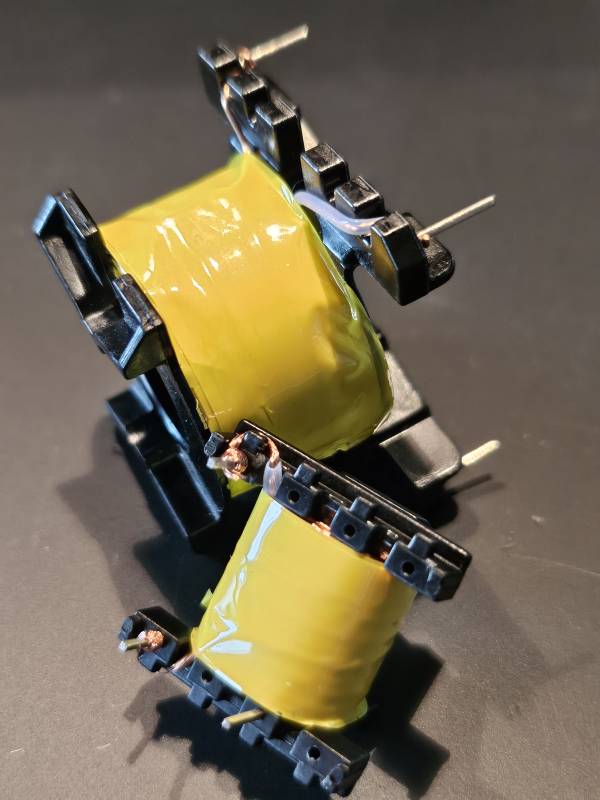

We present a revolutionary machine designed to streamline and accelerate the production process for coils and small transformers. In addition to winding and taping the coils, this solution features a key innovation: the automatic insertion of the insulating sleeve (PTFE or silicon-fiberglass) onto the wire.

Advantages

The machine not only winds and tapes the wire onto the coils, but also autonomously performs the precise placement of the insulating sleeve.

Its advanced system ensures high accuracy in both winding and sleeve insertion, minimizing errors and material waste.

Designed to work with various types of wires and insulating materials, the machine easily adapts to a wide range of applications.

By performing multiple tasks in a single cycle, the machine reduces production time, thus lowering operational costs.

Three versions to meet every need

EUBT - Semi-automatic benchtop model

The smallest in the family: semi-automatic winding and taping with manual loading and automatic sleeve insertion in masked time.

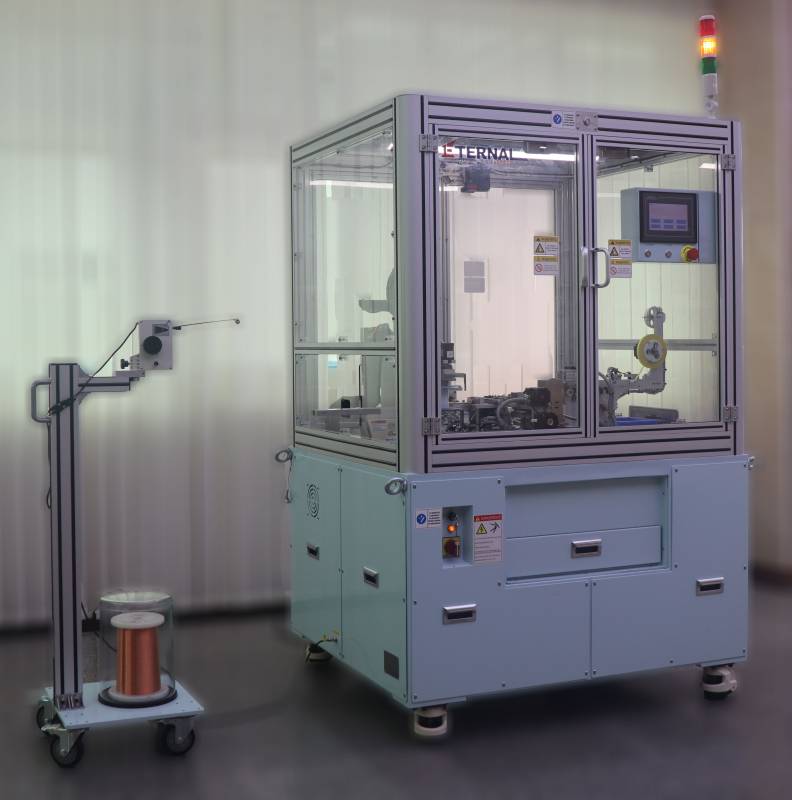

EZTU - Stand-alone automatic model

A fully automatic stand-alone machine with bowl-feeder and single head for winding, taping, and sleeve insertion. It can be customized with various accessories and features.

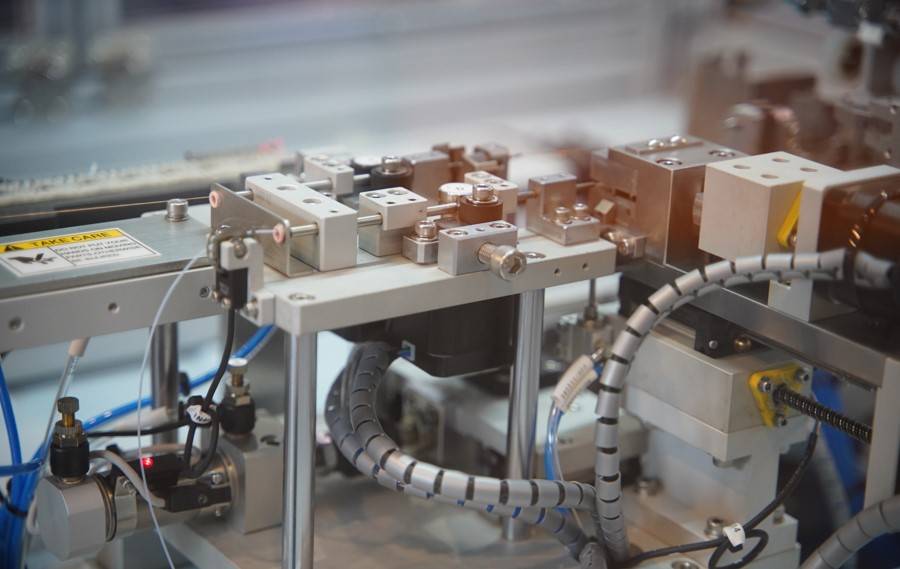

Automated line

We offer winding lines composed of multiple stations -one for each winding layer- suitable for winding layers with different wires,. This represents the highest level of automation, minimizing production times, errors and labor costs.