Standard technical specifications

The data presented in this table are indicative and may vary based on construction needs or project modifications.

-

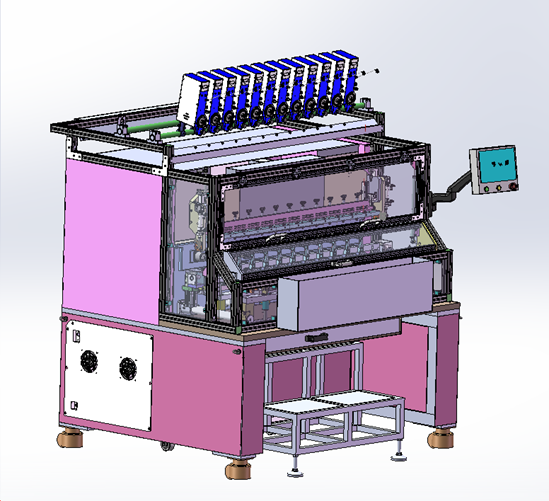

Spindles No. 6

-

Center distance 100mm

-

Machine body dimensions 1100x1200x1700 mm

-

Machine weight (estimated) 810 Kg

-

Spindle servo motor power 1.5 KW

-

Spindle speed 12000 rpm

-

Shaft power 400W (XYZ)

-

Travel distance (mm) X: 110 Y: 120 Z: 80

-

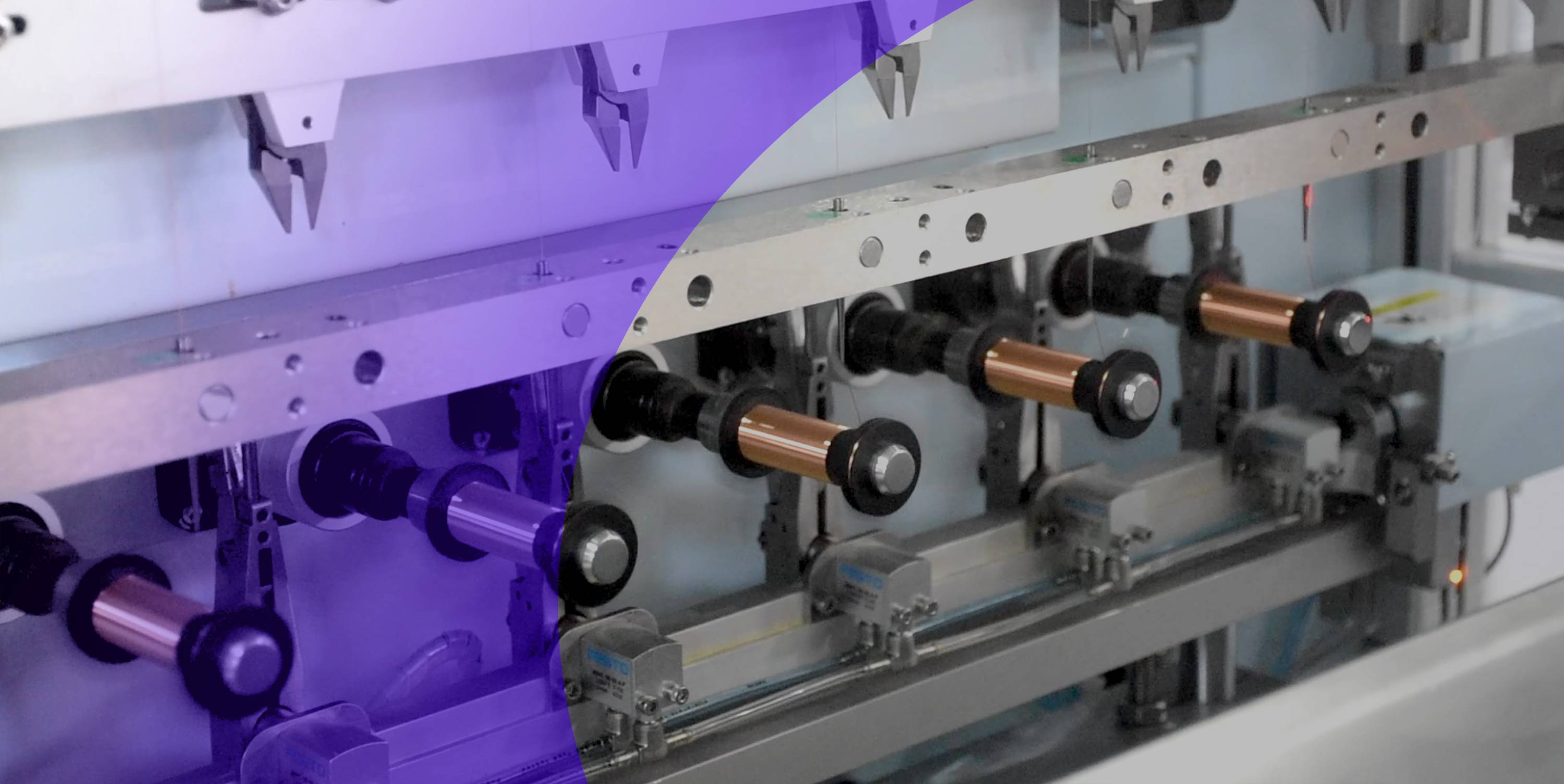

Wire range 0.03-0.80mm

-

Power voltage AC 220V +/- 10%

-

Power 3.6 KW

-

Spindle diameter Ø 12mm

-

Traverse speed (mm/sec.) 80 mm/s

-

Air pressure 0.4-0.6 mpa

-

Bobbin max outer diameter 80mm

-

Spindle direction Clockwise / Counterclockwise

Configurations

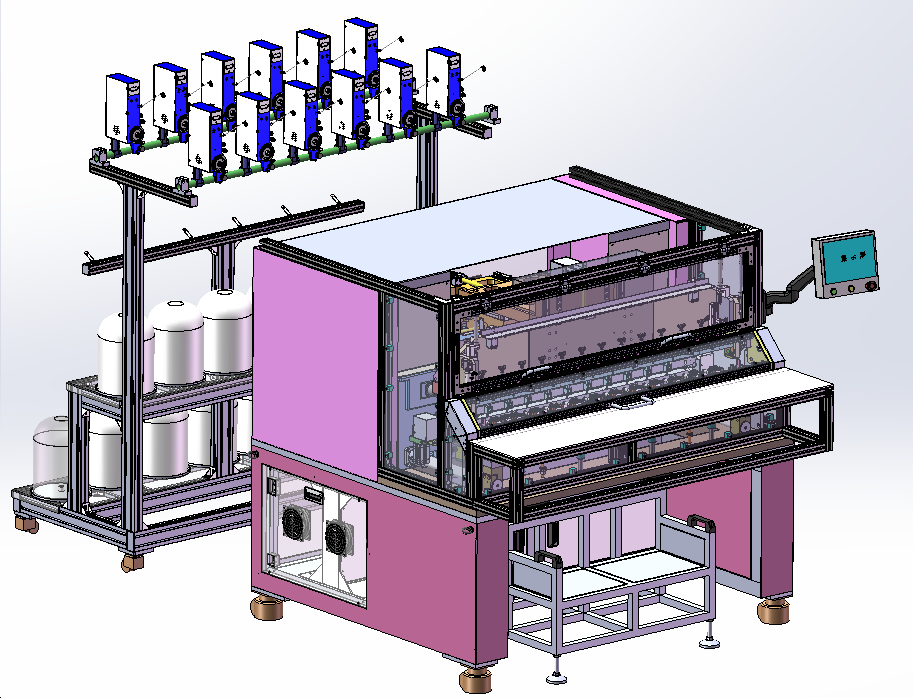

We provide a spool holder stand with our machines, useful for easily positioning and moving small wire spools. Tensioners can also be placed on the stand to facilitate their replacement.

The rear placement of the tensioners allows for the cart to be moved during product changeovers while leaving the wires inserted in the tensioners, speeding up the production changeover process.

Each machine is supplied with a set of tungsten carbide nozzles, according to the customer's needs or requests.

The mobile ladder is useful for assisting operators in the wire threading operations, particularly for customers who require the standard placement of the tensioners above the machine.

We offer the option to position the tensioners in two different ways: above the spindles or behind the machine, usually mounted on the spool holder stand, based on the customer's choice.

Additionally, by using the Bip.0.0 tensioner, we provide the option to have the screen and buttons of the tensioner located at the front when positioned above the machine, or at the back when the tensioners are placed behind the winding machine.

We offer these different solutions to meet the operator's needs for convenience and speed during wire changeovers while working on the machine.